Ebonprex fingerboards with saddle and nut

In stock

Ebonprex fingerboards

Ebonprex is an innovative material that solves many of the problems of stability, hardness and aesthetics of ebony fingerboards currently on the market. Ebonprex is made of thin strips (0.8mm) of dyed beech glued unidirectionally under pressure. With this system, a density of 1.2 t/m3 is achieved, complete stability, extreme hardness and resistance to wear, a high speed of sound transmission and aesthetically it has nothing to envy to the old dense and black ebony now protected by CITES and no longer available for the production of fingerboards.

Features

Fingerboards come with lower and upper nut of same material.

Ebonprex is an innovative material that solves many of the problems of stability, hardness and aesthetics of ebony fingerboards currently on the market. Ebonprex is made of thin strips (0.8mm) of dyed beech glued unidirectionally under pressure. With this system, a density of 1.2 t/m3 is achieved, complete stability, extreme hardness and resistance to wear, a high speed of sound transmission and aesthetically it has nothing to envy to the old dense and black ebony now protected by CITES and no longer available for the production of fingerboards.

Features

- visually similar to ebony; great finished surface quality

- best workability

- best dimensional stability, high rigidity

- high sound conductivity

Fingerboards come with lower and upper nut of same material.

Details

Information for violin makers

The mass, shape and frequencies of the fingerboard plays a major role in the sound quality of the instrument. Thanks to the high rigidity and density of our materials, fingerboards can be made thinner than those made of the lower quality ebony that is found today.

WARNINGS

With or without glue channel

The glue channel not only helps in gluing the fingerboard, but also reduces the mass which is an further advantage for the sound.

Fingerboard specifications

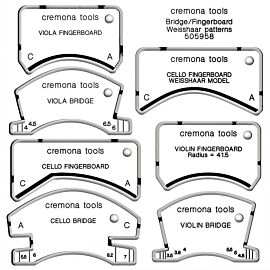

The fingerboards developed and manufactured in Swiss by Wilhelm Geigenbau are produced to specifications for each of the different instruments of the violin family, and in various materials and designs. The surface is milled precisely so that it could only be sanded.

Dimensions for violin:

Dimensions for viola:

Dimensions for cello:

The mass, shape and frequencies of the fingerboard plays a major role in the sound quality of the instrument. Thanks to the high rigidity and density of our materials, fingerboards can be made thinner than those made of the lower quality ebony that is found today.

WARNINGS

- use a dust mask when sanding

- prolonged contact with water may cause slight swelling along the joints

- swelling may also occur with the keyboard glued while in a UV box, with the instrument kept continuously moist to accelerate the tanning. We recommend removing or covering the ebonprex fingerboard during this process

- Ebonprex is sensitive to exposure to alkaline agents, while it supports acids without problems

With or without glue channel

The glue channel not only helps in gluing the fingerboard, but also reduces the mass which is an further advantage for the sound.

Fingerboard specifications

The fingerboards developed and manufactured in Swiss by Wilhelm Geigenbau are produced to specifications for each of the different instruments of the violin family, and in various materials and designs. The surface is milled precisely so that it could only be sanded.

| Material parameters | Ebonprex | Ebony |

| Density t/m3 | 1.1-1.25 | 0.9-1.2 |

| Compression Hardness (MPa) | 60-63 | 40-60 |

| E-Module N/mm2 | >21.000 | 12.000-19.000 |

| Signal Speed (m/s) | 5000-5300 | 4000-5000 |

| Damping (Q) | 100-110 | 80-110 |

Dimensions for violin:

- length: 270mm

- widths: 25.3mm to 43mm

- edge thickness: 5.3mm

- top/bottom radius 41mm/41mm

- maximum depth of hollow under G/E string: 0.7/0.25mm

Dimensions for viola:

- length: 315 mm

- widths: 25.3mm to 47.5mm

- edge thickness: 5.5 mm

- top/bottom radius: 39mm/41mm

- maximum depth of hollow under C/A string: 0.8/0.35mm

Dimensions for cello:

- length: 585 mm

- widths: 34mm to 64.5mm

- edge thickness: 9 mm

- top/bottom radius: 39.5mm/46mm

- maximum depth of hollow under C/A string: 1.1/0.7mm